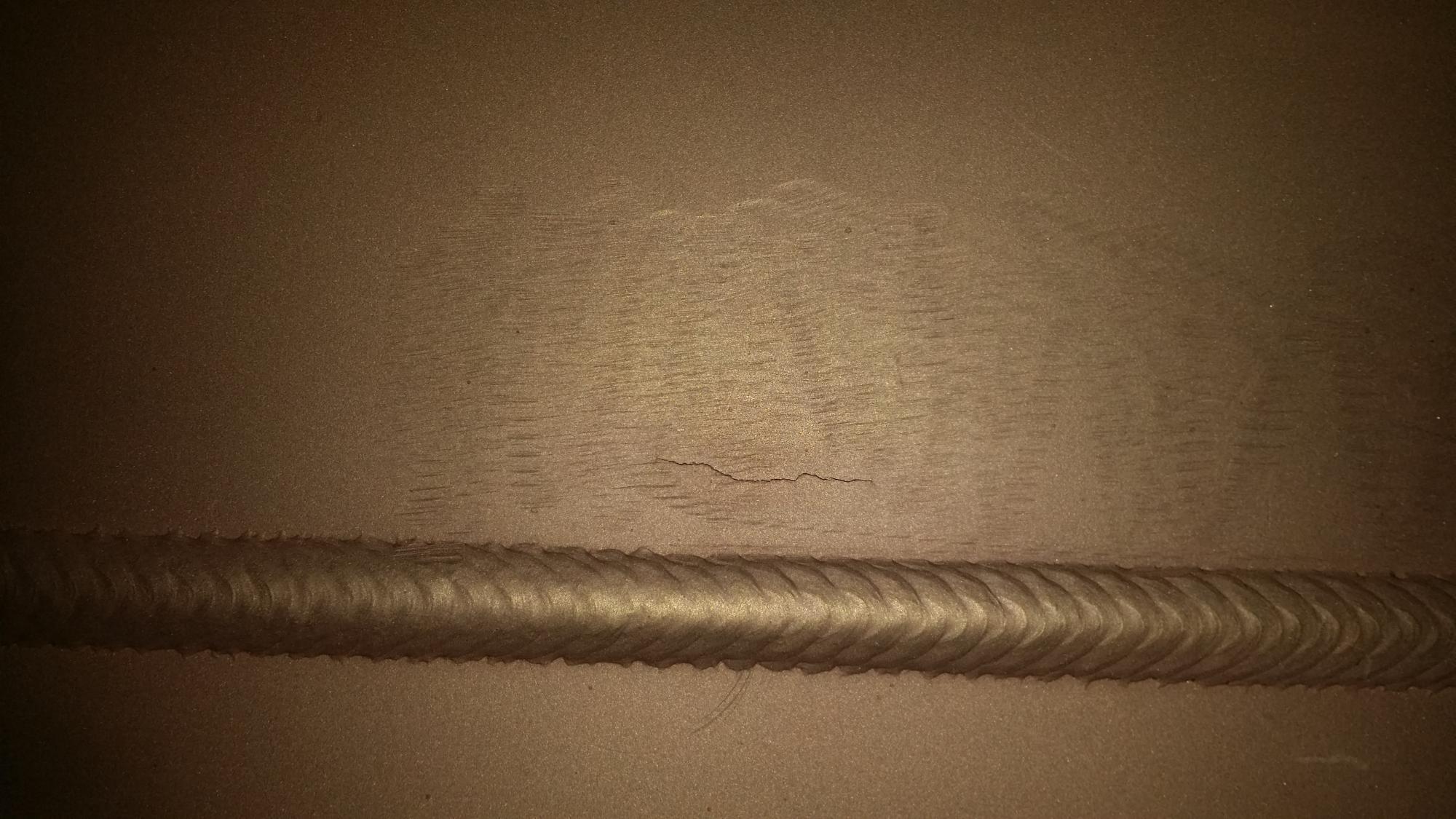

Visual Test Specimens

Interwav specializes in the fabrication of customized visual test specimens containing actual surface breaking cracks with controlled length and opening width. Specimens are ideal for training and testing personnel/hardware in the visual inspection of components where surface cracking is of concern. All specimens are fabricated from stainless steel to prevent degradation due to corrosion and can be populated with various surface features such as weld crowns, scratches, grinding marks, buffed areas, etc.

Cracks not simulations - Surface cracks can be designed based on provided photographs of known cracks if requested. The crack production method utilizes a technique based on fatigue that can result in a crack that appears like intergranular stress corrosion cracking (IGSCC).

General Specifications:

Standard Specimen Dimension: 305mm X 305mm X 305mm

Weld Crown: 12mm to 38mm (typical)

Crack COD (crack opening dimension): 6 to 50 microns

Crack Length Range: 12 to 30 mm

Crack Location: HAZ, weld toe, plate and weld crown

Crack Orientation: Axial, circumferential or angulated

Surface Features: Weld crowns, grinding marks, scratches, gouges and buffed areas

Surface Finish: Sand blasted (typical)

Surface Color: Natural SS, mauve, dark brown, orange/gold