Phased Array Ultrasonic Technique Development

Phased array ultrasonic techniques can greatly reduce inspection times, increase volumetric coverage, improve flaw detection probability, and provide for more intuitative data analysis through coss-sectional imagining. Use of PAUT in place of conventional UT may result in significant cost savings to the customer. Implementation of PAUT typically involves:

Hardware Selection: - Interwav can assist with unbiased instrument selection and probe design/selection.

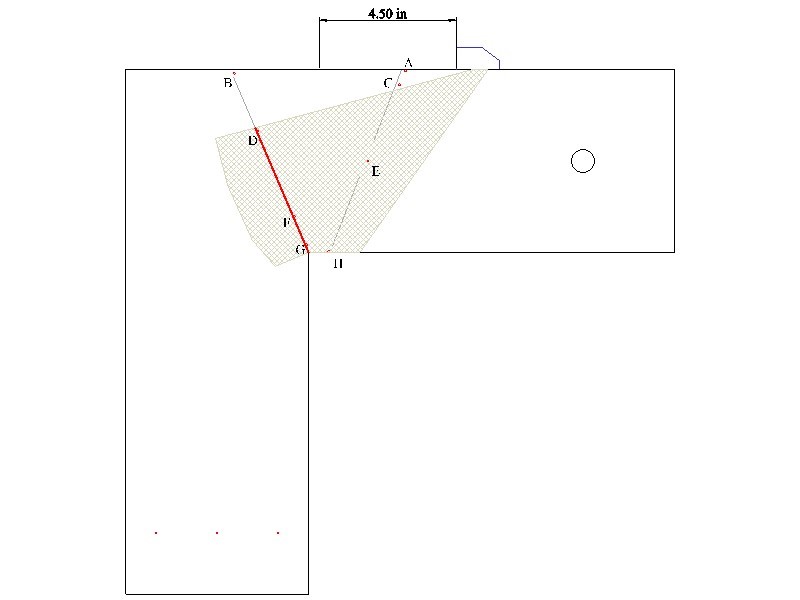

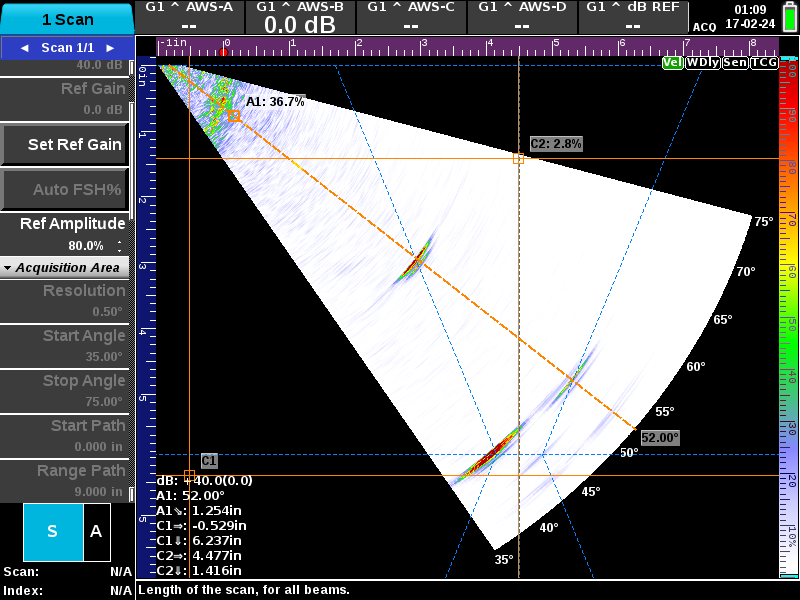

Technique Development - Technical Justification (TJ) documentation describes the basis for scan plans, instrument settings and calibration methods used to achieve a target level of sensitivity, The TJ establishes technique validation from test data collected using mockups that represent component configurations that contain known reflectors. This document is the technical basis from which the procedure is generated and is extremely useful for training.

Procedure Development - Inspection procedures are an essential component in all ultrasonic inspection applications to assure consistent valid inspection results. PAUT procedures differ significantly from conventional UT procedures from calibration methodology scan plan requirements, data analysis methods and system checks. Interwav provides procedures that are instrument specific that guide the operator using step-by-step instructions.

Personnel Training - Interwav provides procedure specific training to assure correct implementation of the PAUT technique.